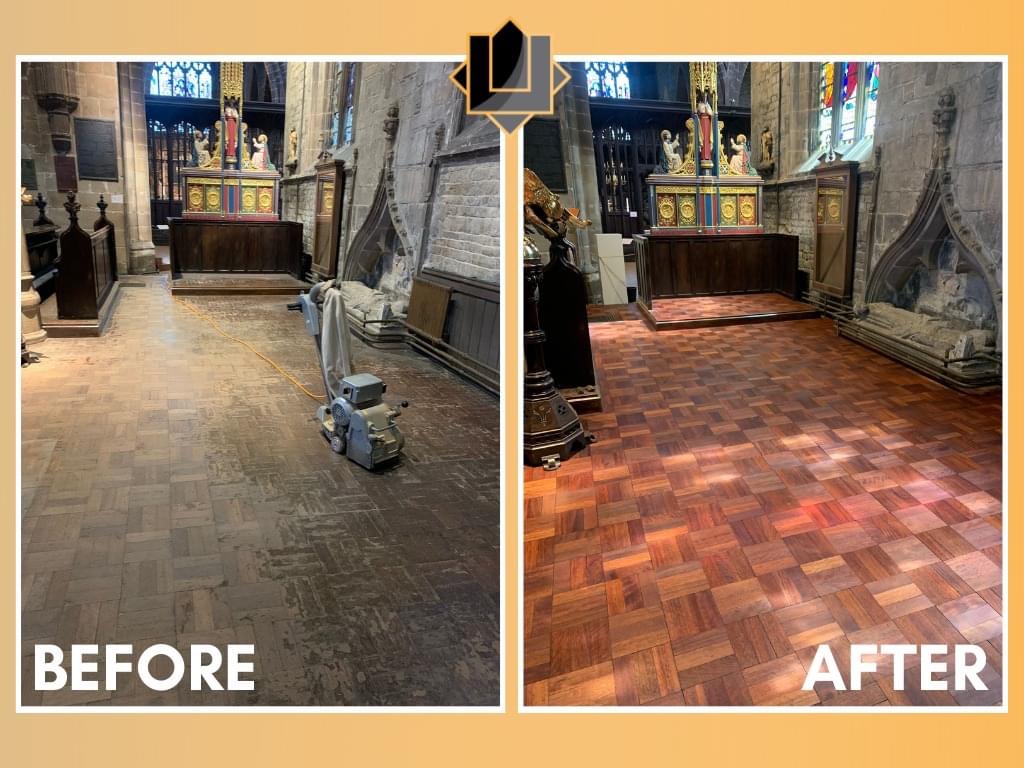

Case Study of the Church of St Mary's and All Saints in Chesterfield (The Crooked Spire)

The Church of St Mary’s and All Saints in Chesterfield is more commonly know as The Crooked Spire. This was the beautiful surrounding for our recent commercial wood floor restoration.

The building of the church began in 1234AD, although the present church dates back to the 14th century. The church itself is full of some amazing architecture.

We were there to restore the some what newer floors, the yang teak installed in the 1950s and the rest of the wooden flooring around the same time.

These floors have been sanded previously at some point and had a varnish applied to them. Over the years of use this has worn away and become discoloured.

The maintenance had consisted of general mopping and applying a general floor polish, which has built up over the years becoming very thick and discoloured in most areas, or completely worn away to the bare wood in the higher traffic areas.

The aim was to get the floors back to the original appearance and apply a finish to allow the floor to be easily maintained.

Following discussion with the church warden, we looked at two methods to achieve this goal.

Option 1: Sand the floor working up to 120 grit, apply pall x325 primer followed by 3 coats of Pall x98 gold matte 2k (which is a commercial lacquer) that creates a hard wearing finish on top of the wood. The maintenance for this would be to clean using a flat mop or 2 standard mops system, with the neutral cleaner we provide.

Option 2: Sand the floor up to 120 grit as with the lacquer, water pop which will open up the grain of the wood followed by applying Magic Oil 2k Ergo with a trowel and buff the excess away. The maintenance for this finish is to clean as before, and periodically apply magic oil care to replenish the oil within the wood. Another plus point to this product is if an area became damaged, it could be sanded and re oiled without having to re sand the full floor.

Work would need to be completed while the church was still open, holding mass, and funerals along with the hundreds of daily tourists and regular church goers.

This also had to be taken into factor when completing the work and choosing the finish.

Magic oil ergo has a full cure time of 12hrs meaning the floor can be used pretty much as normal soon after our completion.

The primer x325 and lacquer x98 gold matte option would be closer to 7 days full cure time depending on the humidity, as we are applying primer and then 3 coats of lacquer (standard commercial practice).

It was decided that the Magic Oil Ergo option would be the best approach.

This was not just down to the minimal duration of time needed to keep off the floor, but down to the fact if maintained well with the cleaner and maintenance oil used regular on it, this would prevent the floor needing sanding for longer, increasing the overall life of the floor before it needs replacing.

We spoke to the head of Pallmann Uk about the project to which they generously provided the Magic Oil Ergo free of charge for the church!

The Hemmings team (Myself) Paul, Will and Jake commenced work on the 28th April 2022

Day 1

We made a start belt sanding two of the wood floors together, as with many older properties power supply can be a bit of an issue, although we tested the sockets and ran the machines for a small time it became evident that the two belt sanders, Pallmann Viper and Cobra would be too powerful for the system.

This meant we had to change our normal course of action and do some edging and corners on 1 floor using the gecko flex connected to a vacuum system, while the other was being belt sanded using a 40 grit to remove all the old finish and level the floor.

Once the old finish was removed on all floors we moved onto using the Pallmann Spider for the next few grits, starting on the 40grit to remove the 40 grit from the belt sander then onto 60-80-100 grit. This process was also completed with the edger to match.

On day 1 we managed to all the floors sanded up to the 100 grit with some small bits of corners to touch up on.

Day 2

Day 2 starting at 8am we had to work efficiently, we needed to out for the church ready for Mass from 12:30 until around 1 and then a they would need to be setting up for a funeral at 2:15.

We began by using the Spider to complete a 120 grit and on one half or the floors, followed by the water pop stage, as that dried we did the 120 grit on the remaining floors.

We had just enough time to apply the magic oil ergo to 1 section of the floors, applying the oil using trowel, leaving around 15 mins to penetrate into the wood before buffing away and excess and a final buff/polish with a white pad.

After mass we had about 1hr to complete the same process on the remaining areas, this is where all the planning came together as we finished at the perfect time ready for the warmer and vicar to prepare for the funeral.

The floors look amazing and a massive transformation as you will see from the photos and video of the project.

Since completing, the Church is so pleased and the amount of positive comments from visitors regarding the finish and look of the floor.

We are now looking how we can help make the terrazzo and stone flooring ares get back to their best also.

Hopefully soon we will have another case study of those floors.